Fiberglass Rebar: the Future of Sustainable Infrastructure

As the demand for sustainable infrastructure increases, a renewed look at whole-of-life cycle savings and the ongoing cost of corrosion is challenging engineers to look beyond conventional construction materials.

Glass fiber-reinforced polymer (GFRP) composite rebar, also known as fiberglass rebar, is one such material that in eliminating the risk of corrosion, is proving to be a leap forward in extending the asset lifespan of structures.

Steel and reinforced concrete are the primary materials that are at risk of corrosion in major infrastructure (Source. Australian Corrosion Association).

Mateenbar™ is designed for use in challenging and corrosive environments – where steel rebar often fails. Mateenbar™ has a unique combination of mechanical properties that offer a superior alternative to other types of rebar, particularly when working in aggressive environments including:

- Corrosion-resistance (No concrete cancer or rust)

- High tensile strength (Twice the strength of steel)

- High durability (Over 100 years of retention of strength and modulus in high pH environments)

- Lightweight (4x lighter than steel).

The lightweight nature of GFRP rebar not only makes it more cost-effective to transport but also significantly reduces the physical strain on workers during installation. This quality is particularly beneficial in large-scale construction projects where heavy steel reinforcement can lead to worker fatigue and potential safety concerns. The ease of handling allows for quicker and more efficient installation, ultimately saving both time and labor costs.

Corrosion Costs

Corrosion costs governments, asset owners, and the wider community. Proximity to the ocean, sea spray, weather, de-icing salt, inadequate corrosion protection or poor maintenance programs are all contributing factors that inevitably lead to costly reparation work and a shortened asset life. The cost to the economy and ratepayer is ongoing.

The cost of corrosion-related maintenance of infrastructure (e.g. bridges, tunnels, seawalls) in Australia is currently estimated to be $A8 billion. This does not include the cost of corrosion to housing. Steel and reinforced concrete are the primary materials that are at risk of corrosion in major infrastructure (Source. Australian Corrosion Association).

A sustainable approach to infrastructure can be achieved by reducing the need for maintenance and eliminating corrosion risk. With a long and costly history of corrosion, steel is no longer viewed as a cost-effective option in aggressive environments, and as a result, the uptake of composite rebar is growing worldwide.

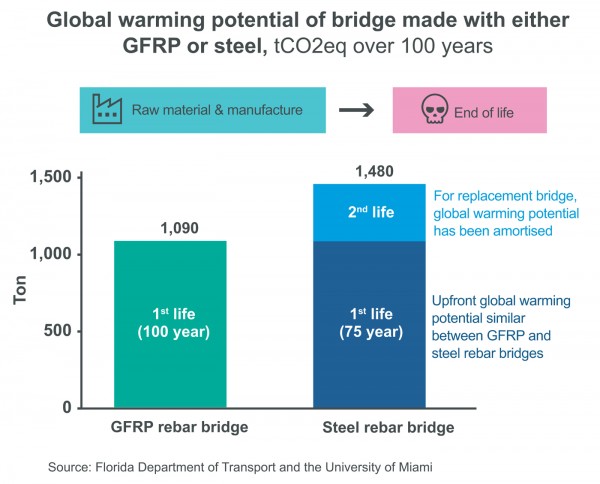

A 100-year life-cycle assessment of a 57m x 18m bridge undertaken by the Florida Department of Transportation and the University of Miami revealed that a composite-reinforced bridge lowered global warming potential by 390 Ton (or 26%). Please view the diagram below:

Glass Fiber-reinforced Polymer Rebar used in Bridges, Tunnels and Seawalls

Mateenbar™ has been used in well over 2000 projects worldwide including:

Northside Storage Tunnel, Sydney, Australia: GFRP composites are suitable for corrosive tunnel environments, providing long-lasting structural integrity and reducing the risk of costly corrosion-related damage. Composite bolts were developed based on the Mateenbar™ technology to provide 30-tonne capacity in the Northside Tunnel.

Jizan Flood Channel, Saudi Arabia: The 23km, 40m wide channel is critical to the city of Jizan. This area is prone to flash flooding and is home to an Aramco oil refinery. The channel was designed to be corrosion-free and highly chemically resistant. Mateenbar™ was the majority supplier for what is the largest GFRP-reinforced project in the world.

Old Youngs Bridge Repair, Oregon, USA: To achieve the goal of reducing maintenance costs and subsequent traffic delays across this main arterial route, fiberglass rebar was used for the cantilever bridge deck.

Structural Engineers use Mateenbar™ Fiberglass Rebar

The uptake from the engineering community has been gradual but is gathering momentum. With 30 years of dedicated research, worldwide standards of design and compliance, optimized product developments, and decreasing prices, composite rebar is paving the way for a future of lasting infrastructure.

Fiberglass rebar technology has improved over the last decade and with enhanced manufacturing efficiencies, the cost of fiberglass rebar has reduced in both upfront costs and whole-of-life savings – this is ultimately accelerating adoption.

GFRP Design Codes and Transport Department Approvals

With comprehensive GFRP rebar design codes, standards, and academic research to support GFRP rebar use, structural and civil engineers are selecting composite rebar as a superior alternative to steel in corrosive environments or where they require non-conductive reinforcement.

The advances in GFRP rebar technology have been welcomed by engineers who are committed to designing sustainable and cost-efficient infrastructure. Composite rebar has also gained the interest of leaders in construction as governments and private firms alike are looking to alternative materials to increase asset life span, reduce costly repairs, and build lasting structures.