Manufactured in the United States and made from durable Glass Fiber Reinforced Polymer (GFRP), Mateenbar60™ is corrosion-free, chemical-resistant, and engineered to deliver a sustainable 100-year design life with no maintenance required—outlasting steel in even the harshest environments.

Designed for heavy industrial projects and larger structural applications, Mateenbar60™ combines trust, quality, and performance to meet your structural reinforcement needs. Despite its lightweight nature, Mateenbar60™ boasts high tensile strength, making it a dependable choice for bridges, multi-story buildings, and other demanding infrastructure projects.

Prefabricated bends are available upon request, offering added versatility for customized project needs, making it easier to meet specific design requirements. Trusted by professionals worldwide, Mateenbar60™ reinforces the critical infrastructure that connects communities and supports progress for generations to come.

Industry Codes & Standards

Mateenbar60™ meets or exceeds all applicable industry codes, standards, and specifications, including:

- ASTM D8505

- ACI 332

- ACI 440

- ICC-ES 5548.

At Mateenbar®, we are committed to delivering reliable concrete reinforcement the industry can trust. For detailed technical information, visit our Tech Data & Approvals page.

Distinctive Features

Mateenbar60™ is not your typical fiberglass rebar. Our engineers ensure that our GFRP products stand above the competition, with unique features including a buffed, and helically ground rib design that is optimized for superior bond strength with concrete. This innovative form factor ensures a long shelf life without deterioration and makes for easy handling.

A Trusted Choice Worldwide

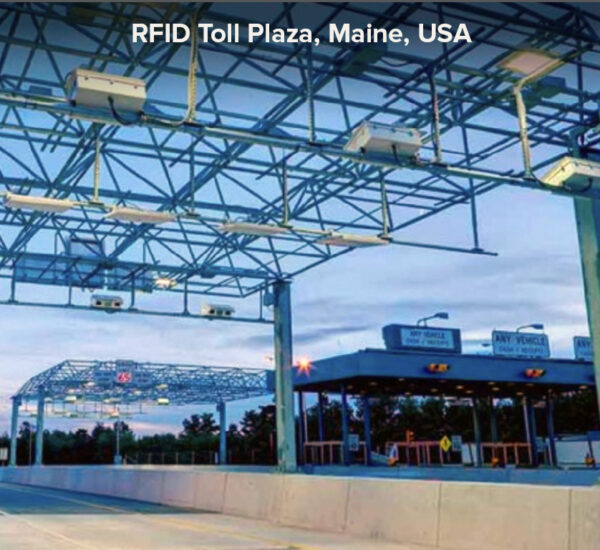

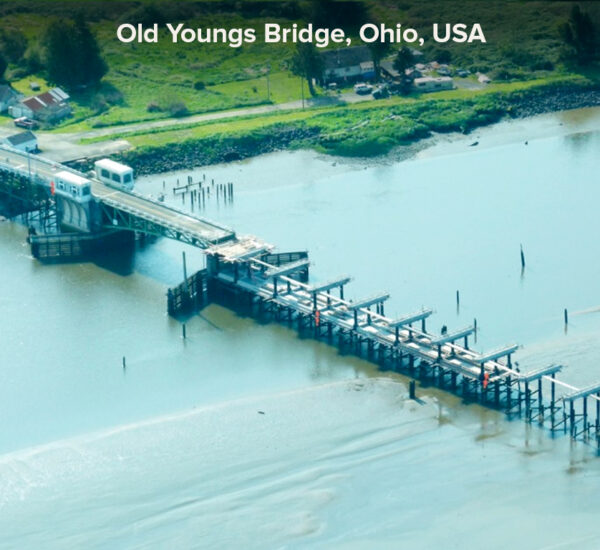

For over 30 years, Mateenbar60™ has earned the trust of contractors, builders, and developers across the globe. From home projects to F1 Racetracks, our fiberglass rebar has produced the most dependable results for concrete reinforcement worldwide. No matter where or what the requirements are, Mateenbar60™ will deliver the value your project deserves.

Sustainable Solutions That Deliver

At Mateenbar®, sustainability is more than a feature—it’s a commitment. From reducing emissions to designing products with a 100-year lifespan, we prioritize eco-friendly practices in everything we do. By creating smarter, safer, and more durable solutions, we’re shaping a future where innovation meets responsibility.

Maximized Capacity

Mateenbar60™ is lighter than steel, resulting in reduced transportation costs and emissions. Efficient logistics are now possible, delivering larger quantities per trip with fewer resources.

Optimal Durability

Engineered for a 100-year lifespan, Mateenbar60™ is corrosion-free, eliminating internal pressure on concrete to extend structural durability and reduce maintenance costs and repair needs.

Enhanced Safety

The light weight of Mateenbar60™ simplifies handling, minimizes installation risks, & reduces workplace injuries—contributing to safer worksites & reducing material waste for a more sustainable future.

Dimensions and Availability

Straight Bars

Prefabricated Bent Bars

Is Mateenbar60™ Fiberglass Rebar Made in USA?

Mateenbar60™ fiberglass rebar is proudly manufactured in the USA at our production facility in North Carolina. This ensures compliance with key domestic sourcing requirements such as Buy America and BABA (Build America, Buy America). Manufacturing locally allows us to provide faster response times, stronger quality assurance, and a product customers can trust to perform on every job—avoiding the potential risks associated with offshore manufacturing. By producing in the USA, we proudly support American jobs and infrastructure projects, contributing to the growth and sustainability of the domestic economy.

How Is Mateenbar60™ Packaged?

Mateenbar60™, just like our other product, Greenbar2X®, is manufactured and shipped in the USA. Master bundles are available in standard sizes. Stock bent bars are available on request. For more info on packaging, see the Mateenbar60™ Product & Technical Information Sheet.

What Is Mateenbar60™ Used For?

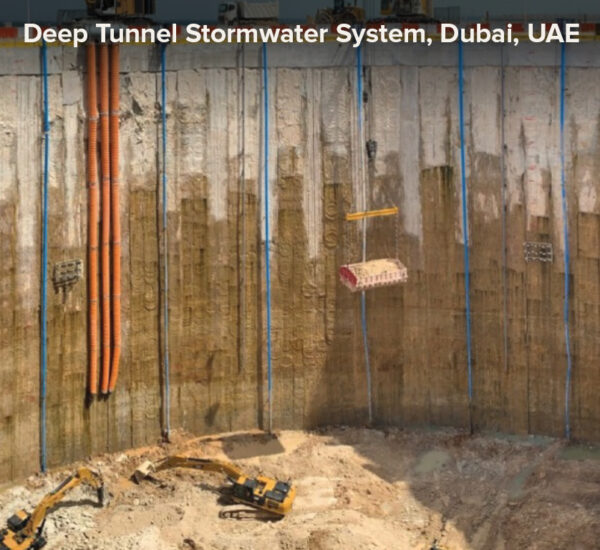

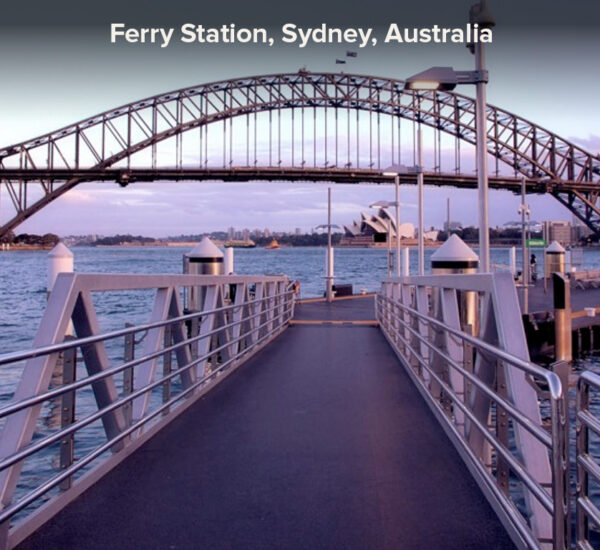

Mateenbar60™ is a rust-proof, lightweight structural rebar designed to reinforce concrete in heavy infrastructure and government projects. It is the primary reinforcement to provide resistance for the load stresses on the concrete structure according to ACI440 / ASTM D8505 standards and replaces epoxy-coated steel, galvanised steel and stainless steel where durability and maximum performance are critical. Its stiffer modulus of 8700 ksi (60 GPa) makes it ideal for large-scale applications, including bridges, highways, seawalls, industrial facilities, and other heavy-duty construction.

Is Mateenbar60™ Approved by the Building Codes?

Mateenbar60™ complies with key building codes and standards established by leading industry institutions such as ASTM, ACI, and ICC. These standards and evaluations ensure Mateenbar60™ meets the stringent requirements for safety, performance, and reliability in residential and commercial construction. While specific building codes can vary by jurisdiction, Mateenbar60’s™ compliance with these widely recognized standards simplifies the approval process for use in many projects. For detailed information, consult your local building authority.

Is Mateenbar60™ Affected by Alkaline Conditions?

No, Mateenbar60™ is not significantly affected by alkaline conditions. It is manufactured with ECR glass fibers, which are resistant to attack from alkaline conditions and a specialized resin matrix that provides excellent resistance to the high-alkaline environments typically found in concrete. This ensures long-term durability and performance, even in harsh conditions, making it a reliable reinforcement choice for a wide range of applications.

Does Mateenbar60™ Have a Ductile Failure?

Mateenbar60™ does not experience ductile failure like steel. Instead, it exhibits a linear elastic behavior until it reaches its ultimate strength, at which point it will fail in a brittle manner consistent with the properties of FRP materials without significant deformation. The design standards for GFRP rebar like Mateenbar60™ allow for this property by incorporating safety factors and providing reliable and long-lasting reinforcement.