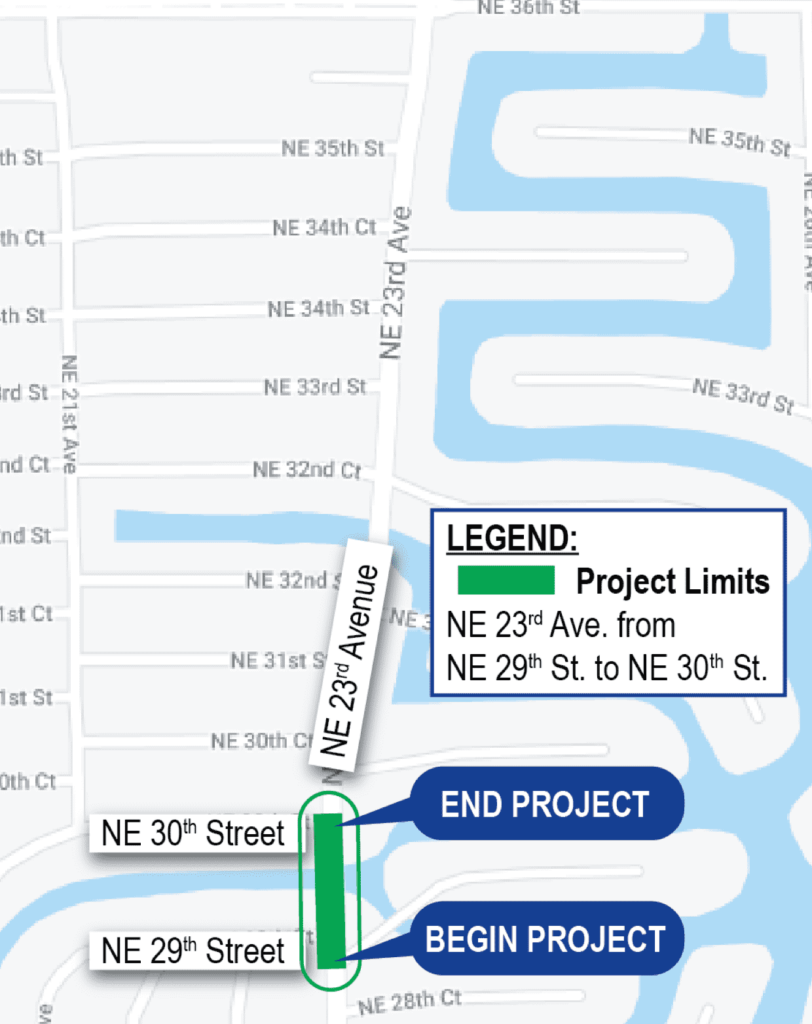

NE 23rd Avenue Bridge Replacement, USA

Project Overview

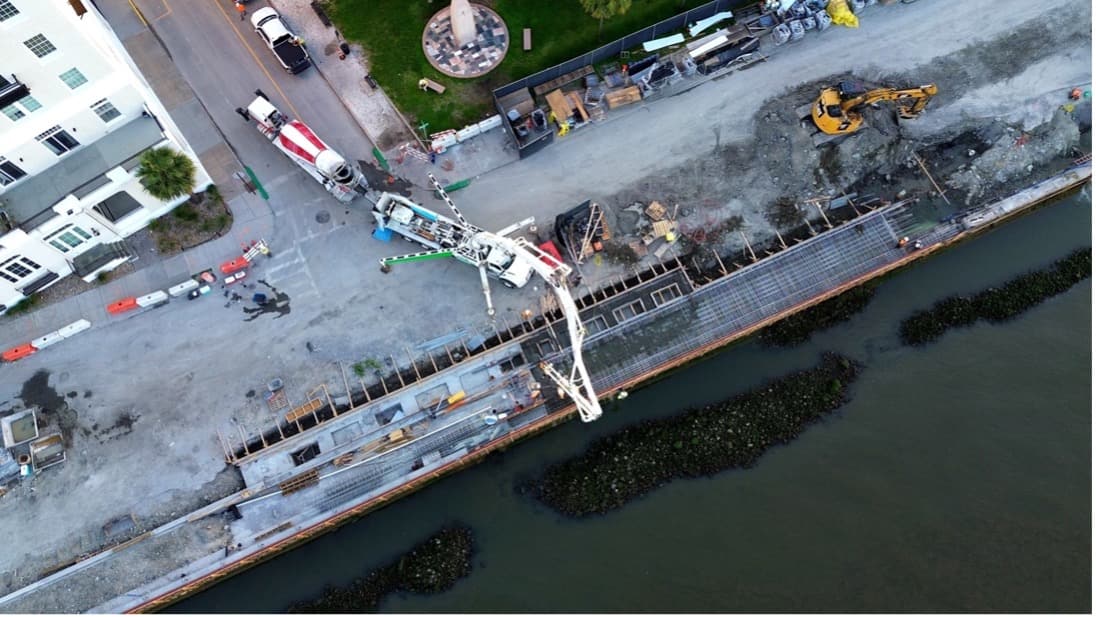

The NE 23rd Avenue Bridge project involved replacing a deteriorated three-span low-level bridge and its associated abutment bulkheads.

Bridge inspection reports had revealed significant structural wear, including evidence of corroded steel reinforcement–raising long-term concerns about durability, safety, and maintenance.

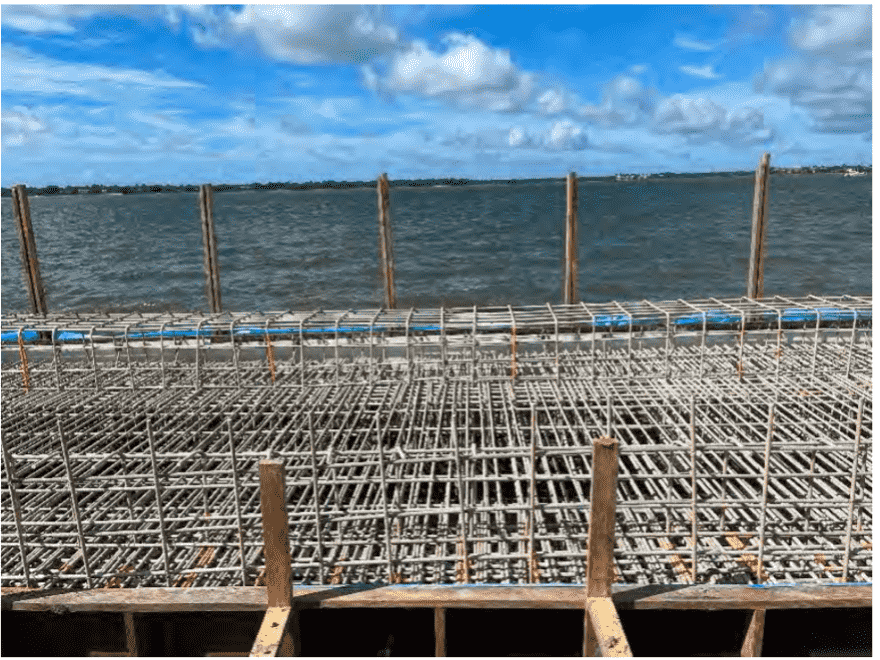

To address these issues, the project team removed the existing structure and installed a new fiberglass rebar-reinforced concrete (GFRP-RC) flat-slab bridge using Mateenbar60™ along with a corrosion-resistant seawall-bulkhead system.

This included the use of fiberglass rebar master piles and GFRP-RC precast panels—an innovative approach that offered a long-term, corrosion-free alternative to conventional steel reinforcement.

This project marked a milestone in Florida infrastructure as the state’s first GFRP-RC 3-span continuous flat-slab bridge and first soldier pile bulkhead-seawall constructed with fiberglass rebar-reinforced precast panels.

Unlike traditional methods that rely on Grade 60 carbon-steel rebar with extensive concrete cover and pozzolan-enhanced concrete mixes, this project utilized fiberglass rebar throughout the splash zone.

This eliminated the need for pozzolanic materials in the concrete mix and allowed for reduced concrete cover, streamlining construction and improving overall durability.

Images courtesy of FDOT.

Project Results

Innovative Engineering Approaches:

- Replaced traditional Grade 60 steel rebar with fiberglass rebar across most structural elements

- Eliminated need for pozzolanic additives in concrete

- Allowed for reduced concrete cover while maintaining structural performance

- Applied fiberglass rebar specifically within splash zone and marine environments

Key Benefits of Using Mateenbar60™ GFRP:

- Exceptional resistance to corrosion in marine and coastal settings (corrosion is one of the main reasons why America’s bridges are aging quickly)

- Simplified mix design and reduced construction complexity

- Longer service life with minimized maintenance requirements

- Lightweight, easy-to-handle reinforcement material

- Supports long-term structural integrity in harsh environmental conditions

This use of Mateenbar60™ GFRP demonstrates how advanced materials can solve real-world infrastructure challenges—delivering smarter, stronger, and more sustainable solutions for large-scale structural projects.

To see another case study for the effectiveness of fiberglass rebar reinforcement, read through our Harker’s Island Bridge post, a landmark structure that’s notable for being the world’s largest bridge built entirely without steel reinforcement.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.