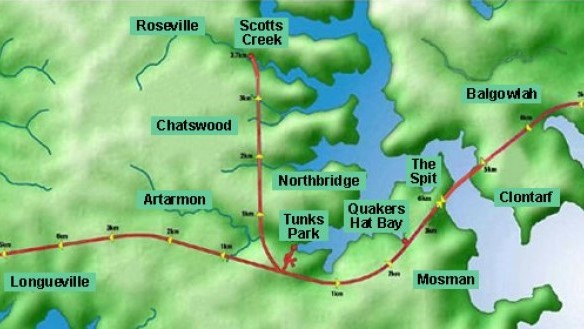

Low Battery Seawall Repair, USA

Project Overview

Charleston’s historic Low Battery Seawall, originally constructed in the early 1900s, has served as a protective barrier and a beloved waterfront promenade along the city’s southernmost peninsula.

Over a century of exposure to the elements, rising sea levels, and increasingly intense storms have led to significant deterioration. Cracks, concrete spalling, and failing timber piling connections have weakened the structure, while settlement behind the wall has created accessibility challenges for residents and visitors.

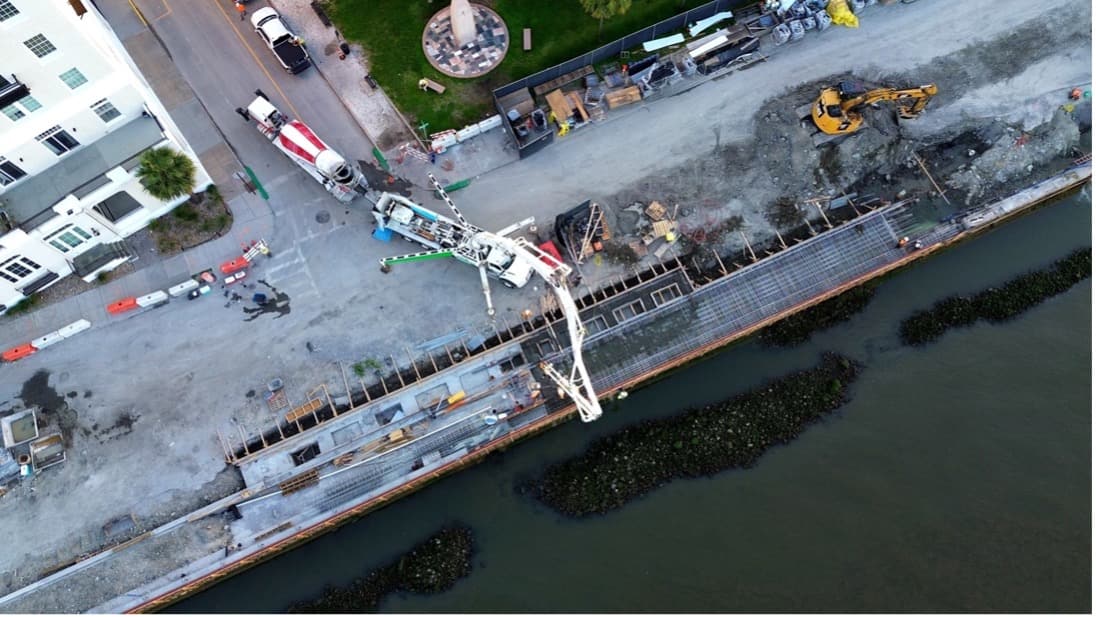

To restore and strengthen the seawall for future generations, the City of Charleston embarked on an extensive renovation project. This included raising the height of the wall to combat flooding, underpinning it with micropiles for added stability, constructing a new concrete pile cap, and supporting the promenade with reinforced concrete to prevent further settlement.

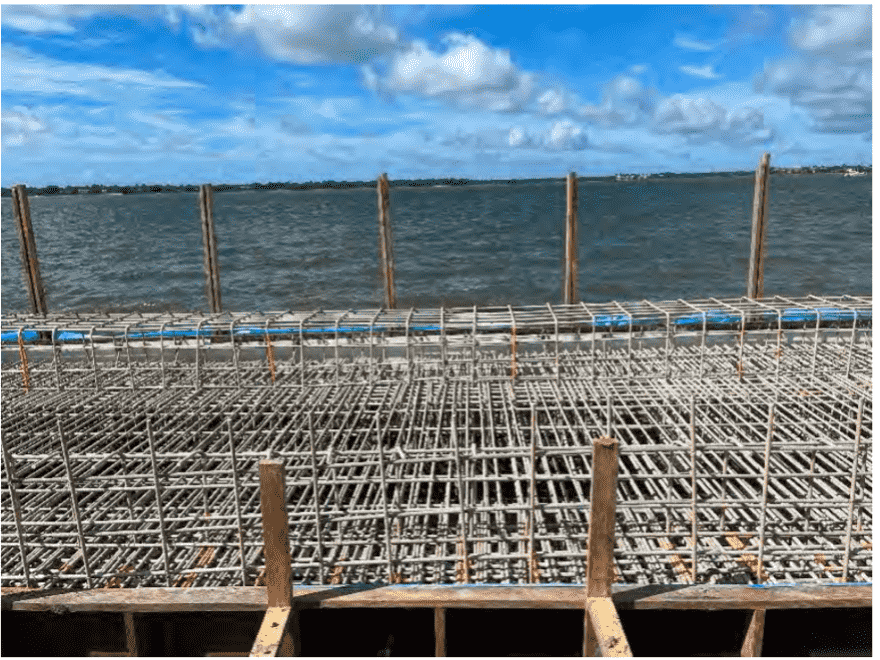

Given the highly corrosive coastal environment, the project required a durable reinforcement solution that would extend the structure’s lifespan and reduce long-term maintenance. This is precisely why Mateenbar60™ fiberglass rebar was chosen as the primary reinforcement for this crucial project.

Project Details

- Scope: Reinforcement of promenade, concrete rail posts, and seawall shotcrete repairs

- Reinforcement Used: 250,000 linear feet of Mateenbar60™ fiberglass rebar

- Completion Date: 2025

- Structure Owner: City of Charleston

- Design Firm: Johnson, Mirmiran & Thompson (JMT)

- Contractors: Gulfstream Construction (general contractor) and Palmetto Gunite (subcontractor)

Project Results

Key benefits of using Mateenbar60™ in this project include:

- Corrosion Resistance: Unlike traditional steel rebar, Mateenbar60™ does not rust or degrade in high-salinity conditions, ensuring long-term structural integrity.

- Extended Service Life: With a lifespan exceeding 100 years, the reinforced seawall will require significantly less maintenance over time.

- Lightweight and High-Strength: Easier to transport (fewer cranes and forklifts needed) and install compared to steel rebar, reducing construction time (GFRP work in Phase III of the project was completed in 7 months instead of the estimated 14 months) and costs.

- Enhanced Accessibility and Resilience: The raised promenade is now ADA-compliant, providing safe access for all visitors while better withstanding future storm surges.

This project is a testament to how innovative materials like Mateenbar60™ are shaping the future of infrastructure by delivering stronger, smarter, and more sustainable solutions for coastal protection. Charleston’s Low Battery Seawall is a treasured landmark, and with the use of superior materials like fiberglass rebar, it is now reinforced to stand strong for another century. The Low Battery Seawall Repair has undergone four phases of construction and is set to be completed in mid-2025.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.