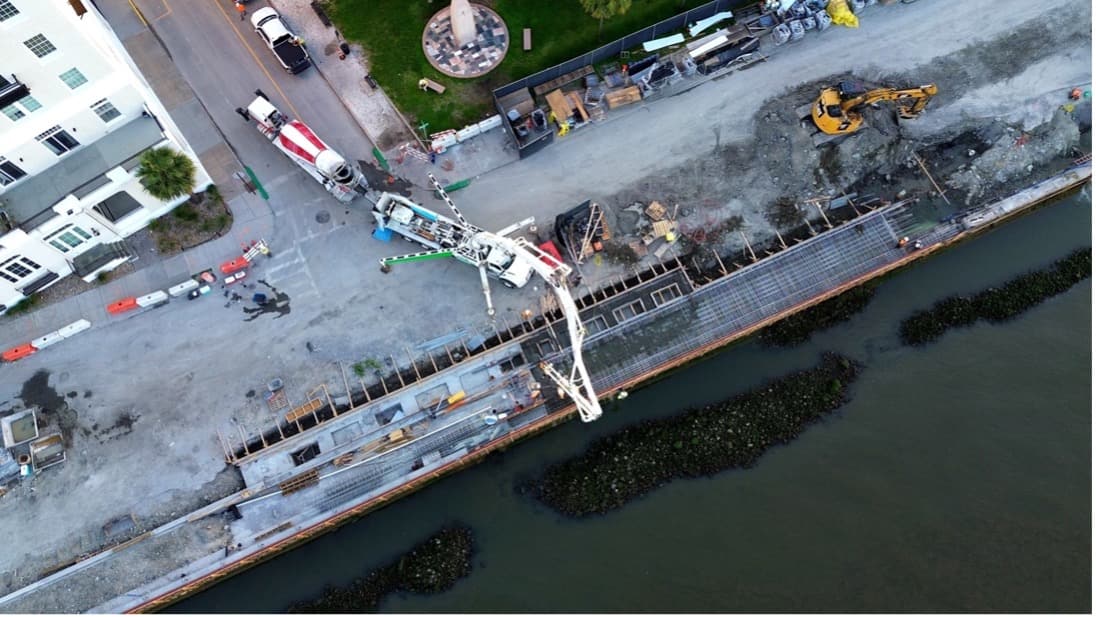

Tauranga Marina Reinforcement, New Zealand

Project Overview

Tauranga Bridge Marina in New Zealand required a reinforced concrete breakwater to protect yachts and powerboats from storm events and the harsh conditions of the marine environment. Ensuring the structural integrity and longevity of the breakwater was essential to maintaining the marina’s long-term functionality and safeguarding valuable vessels.

Traditional steel reinforcement presented significant challenges in a saltwater environment.

Corrosion is a major concern for steel-reinforced structures, leading to rust, structural degradation, and costly maintenance over time. Additionally, the heavy weight of steel reinforcement increased transportation and installation costs, making it a less efficient choice for this marine application.

To address these challenges, Bellingham Marine selected Mateenbar60™ glass fiber-reinforced polymer (GFRP) rebar to reinforce the breakwater’s concrete panels. This advanced composite material provided significant advantages over conventional steel reinforcement, enhancing the durability, efficiency, and sustainability of the project.

Project Results

The use of Mateenbar60™ fiberglass rebar in the Tauranga Bridge Marina breakwater delivered several key benefits:

- Reduced Weight for Easier Handling and Transport: The use of Mateenbar60™ reduced the weight of each concrete panel by two tons, improving transportation efficiency and simplifying handling during installation.

- Superior Durability and Corrosion Resistance: Unlike steel rebar, Mateenbar60™ does not corrode in saltwater environments, ensuring a 100+ year design life and eliminating the risk of rust-related structural damage.

- Cost Savings in Construction and Maintenance: The reduced weight of the panels minimized concrete cover requirements and lowered installation costs. Additionally, the long-term corrosion resistance of Mateenbar60™ eliminates the need for costly repairs and replacements.

- Sustainable and Environmentally Friendly Solution: By preventing corrosion-related maintenance and reducing material waste over time, Mateenbar60™ contributes to more sustainable marine infrastructure.

The Tauranga Bridge Marina breakwater stands as a testament to the advantages of Mateenbar60™ fiberglass rebar in marine construction.

Backed by Pultron Composites’ 40 years of expertise in composite technology, Mateenbar60™ continues to lead the way in durable, corrosion-resistant reinforcement solutions. With superior performance and long-term reliability, it remains the ideal choice for coastal infrastructure projects requiring strength, longevity, and efficiency.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.