Burj Al Arab Seawall Strengthening, Dubai

Project Overview

The Burj Al Arab, Dubai’s iconic seven-star hotel, stands on a man-made island that has been safeguarded by a protective seawall for over two decades.

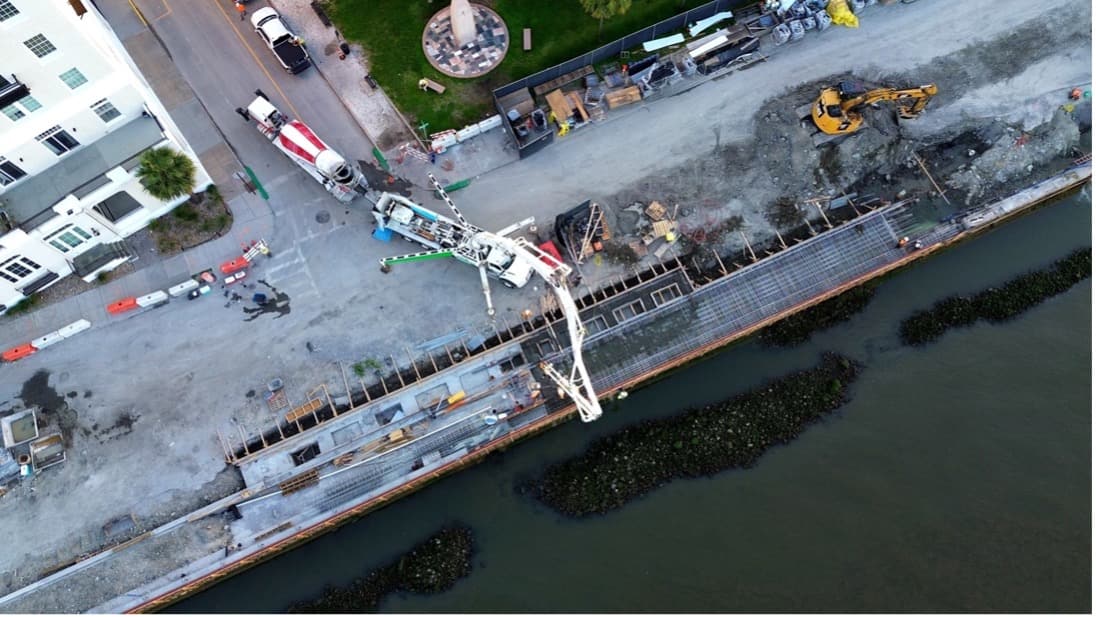

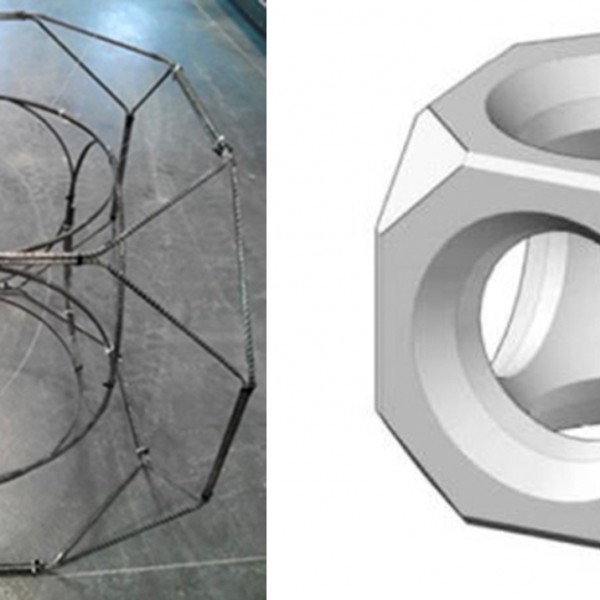

As part of a long-term maintenance program, the reinforcement of 1,500 SHED concrete armor units, which dissipate wave energy and protect the island, was required to ensure continued durability and structural integrity.

Since the island’s construction, advancements in corrosion-resistant materials have provided new opportunities to enhance the longevity of marine structures.

Among these innovations, Mateenbar60™ GFRP rebar has emerged as the preferred reinforcement material for high-exposure environments – which is primarily why it was chosen as the primary reinforcement for the project.

The reinforcement strategy was carefully evaluated by leading design consultants at Atkins, who assessed multiple rebar options before selecting Mateenbar60™ as the ideal solution.

Design studies determined that incorporating Mateenbar60™ into the three tidal-zone layers of SHED units would significantly improve the long-term resilience of the protective seawall while maintaining the aesthetic quality of the Burj Al Arab’s surroundings.

Project Results

The key benefits of using Mateenbar’s® fiberglass rebar on the project include:

- Corrosion Resistance – Unlike traditional steel reinforcement – which is prone to corrosion — Mateenbar60™ does not corrode, making it ideal for long-term use in a harsh marine environment.

- Extended Service Life – Designed for a 100-year service life, Mateenbar60™ ensures long-term durability and structural integrity.

- Reduced Maintenance Costs – By preventing corrosion-related deterioration, Mateenbar60™ minimizes costly repairs and extends the lifespan of the SHED armor units.

- Structural Longevity – The reinforced SHED units provide enhanced stability and resilience against constant wave energy exposure.

- Cost-Effective Alternative – Compared to stainless steel reinforcement, fiberglass rebar delivers superior performance at a fraction of the cost, providing the best whole-of-life savings.

By investing in Mateenbar60™, the Burj Al Arab island will benefit from a more resilient and cost-effective solution that safeguards one of Dubai’s most prestigious landmarks for decades to come.

Check out the Giant Sculpture Project for another case study of how Mateenbar60™ outperforms steel rebar on massive structural projects.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.