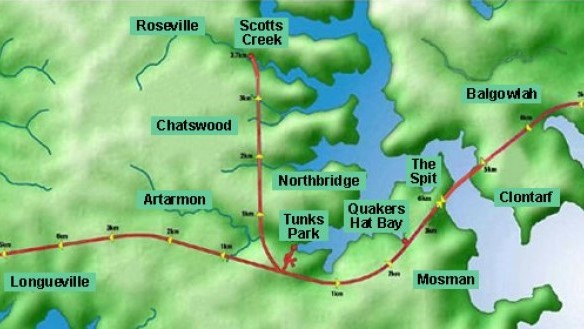

Storage Tunnel Reinforcement, Australia

Project Overview

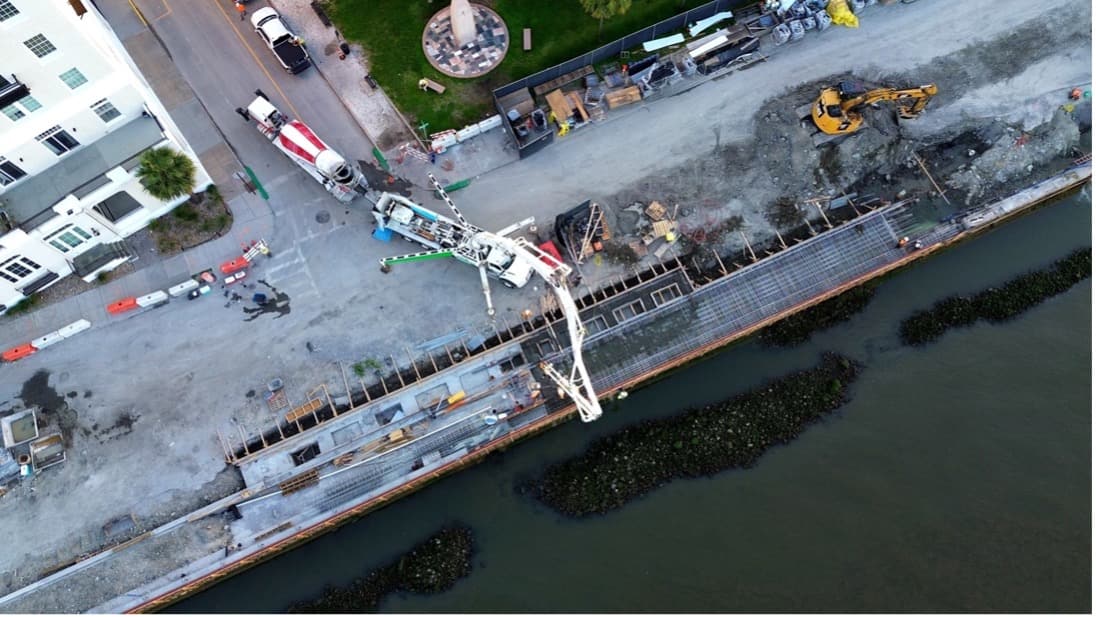

The Northside Storage Tunnel Project was a critical infrastructure development aimed at reducing contamination from raw sewage entering Sydney Harbour.

The project involved constructing about 14 miles of tunnels using four tunnel boring machines (TBMs) and excavating an additional 250,000 cubic meters of tunnels with roadheaders.

Valued at A$460 million, the project was undertaken by an alliance between Sydney Water, Transfield, Connell Wagner, and Montgomery Watson. Work began in February 1998 and was completed within 24 months, meeting the strict timeline required for this large-scale initiative.

Project Challenges and Solutions

The tunnel structure would be exposed to highly corrosive elements, including stormwater and sewage overflow, making traditional reinforcement materials like stainless steel unsuitable for long-term durability.

Engineers needed a reinforcement solution that could withstand chemical exposure while maintaining structural integrity over time.

Glass Fiber Reinforced Polymer (GFRP) composites were identified as the optimal solution.

Unlike steel rebar, GFRP fiberglass rebar does not corrode when exposed to salt water, chemicals, or extreme tunnel environments. This corrosion resistance minimizes long-term maintenance costs and ensures structural integrity over the tunnel’s lifetime.

Mateenbar60™ was selected as the reinforcement material for this project due to its:

- Inherent corrosion resistance, eliminating concerns of material degradation in aggressive tunnel conditions.

- High strength-to-weight ratio, providing exceptional structural performance while being significantly lighter than steel.

- Long service life, ensuring the tunnel remains protected for decades without the need for costly repairs or replacements.

Optimizing Tunnel Construction for Speed and Efficiency

The project was highly time-sensitive, requiring fast excavation and reinforcement installation, particularly in the storage tunnels.

The geology of the region, composed mainly of siltstone and shale bands, posed a challenge.

Traditional steel reinforcement methods would be susceptible to corrosion at stress points, where cracks in the resin encapsulation could allow exposure to moisture and chemicals.

To meet the speed and durability requirements, engineers sought a support system that was:

- Compatible with TBM excavation, allowing for one-shot installation.

- Resilient under stress, minimizing the risk of failure due to geological conditions.

- Lightweight and easy to install, improving efficiency in the tunneling process.

Mateenbar60™ fiberglass rebar met all of these requirements, offering a faster and more reliable installation process compared to traditional materials.

Project Results

Results of the Northside Storage Tunnel Project included:

- 14 miles of tunnels reinforced with Mateenbar60™, ensuring a 100+ year design life.

- Significant reduction in long-term maintenance costs compared to traditional steel reinforcement.

- Improved installation efficiency, reducing project timelines and labor requirements.

- Enhanced resistance to chemical exposure, eliminating corrosion-related structural failures.

By integrating Mateenbar60™ into the Northside Storage Tunnel Project, Sydney Water and its partners successfully created a durable, maintenance-free reinforcement system capable of withstanding the region’s challenging environmental conditions.

This project stands as a model for modern tunnel reinforcement, demonstrating the advantages of fiberglass rebar technology in high-risk infrastructure applications.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.