Gisborne Cenotaph Repair, New Zealand

Project Overview

The Gisborne Cenotaph, a nationally significant monument standing on the Turanganui River bank since 1923, sustained considerable structural damage during a 6.8 magnitude earthquake in December 2007.

The earthquake compromised the monument’s foundation, leaving it vulnerable to future seismic activity and necessitating major reinforcement to ensure its longevity. To protect and preserve the Cenotaph, structural engineers designed a comprehensive strengthening solution.

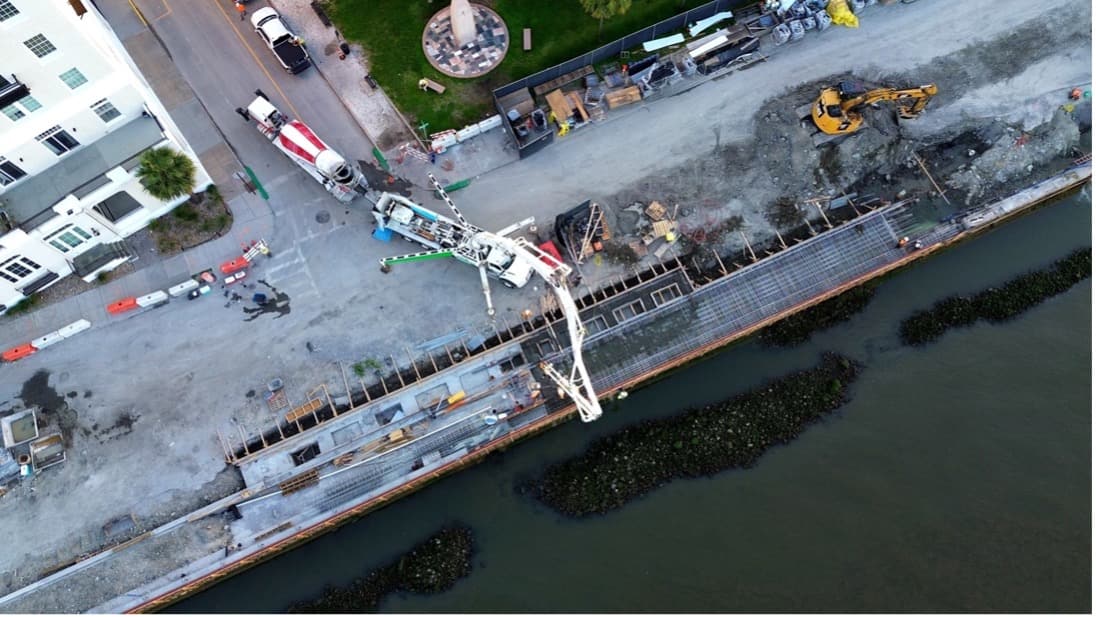

The project involved removing soil around the existing foundation, demolishing portions of the original structure, and constructing a substantial reinforced foundation ring beam.

This new foundation, supported directly on screw piles, was specifically designed to provide enhanced stability for the entire Cenotaph structure.

Given the Cenotaph’s coastal location and high exposure to moisture and salinity, the engineers prioritized durability and corrosion resistance in their choice of materials.

To ensure long-term structural integrity and minimize future maintenance, Mateenbar60™ glass fiber-reinforced polymer (GFRP) rebar was specified for the stirrups and longitudinal reinforcement in the foundation.

Project Results

The use of Mateenbar60™ in the Gisborne Cenotaph restoration provided significant benefits, ensuring the long-term preservation of this historic landmark while also improving efficiency during construction.

- Corrosion Resistance: Fiberglass rebar eliminates the risk of long-term corrosion, crucial for a structure exposed to a coastal environment.

- Enhanced Longevity: By using Mateenbar60™, the new foundation is expected to last over 100 years, safeguarding the Cenotaph for future generations.

- Improved Installation Efficiency: Mateenbar60™ is four times lighter than steel rebar, making handling and placement significantly easier. The 26-foot lengths of #10 rebar were easily maneuvered and installed by just one or two workers.

- Time and Labor Savings: The lightweight and non-corrosive properties of Mateenbar60™ streamlined the installation process, reducing labor intensity and expediting project completion.

- Seismic Resilience: The reinforced foundation provides the Cenotaph with enhanced stability, ensuring it remains structurally sound in the event of future earthquakes.

Mark van Wijk, Project Manager at Currie Construction, highlighted the advantages of Mateenbar60™ fiberglass rebar, stating, “Its weight made it far easier to handle.”

The use of Mateenbar60™ not only simplified construction but also ensures that this historic monument remains a proud symbol of remembrance for another century.

To see another example of how Mateenbar® helped in repairing infrastructure from a natural disaster, read through the State Highway 1 Repair Project in New Zealand.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.