Dibba Seawall Development, Dubai

Project Overview

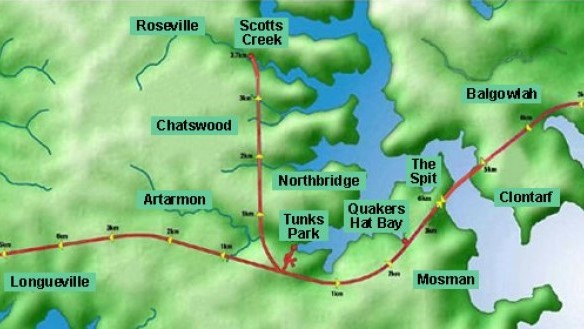

A new marina development along the east coast of the United Arab Emirates features a 0.3-mile-long access canal, allowing light boats to reach luxury housing near the beaches of Dibba Harbour.

To create this canal, the soil was excavated to a depth of about 20 feet, with Mechanically Stabilized Earth (MSE) quay walls providing the necessary structural support.

Given the coastal location and exposure to a highly saline environment, the project required materials capable of delivering long-term durability and resistance to corrosion.

With a service life requirement of 75 years, the design team explored various reinforcement options for the MSE quay walls.

Conventional black steel reinforced pre-cast concrete panels were initially considered but ultimately rejected due to concerns over long-term durability. Similarly, mass concrete panels were dismissed due to higher associated costs.

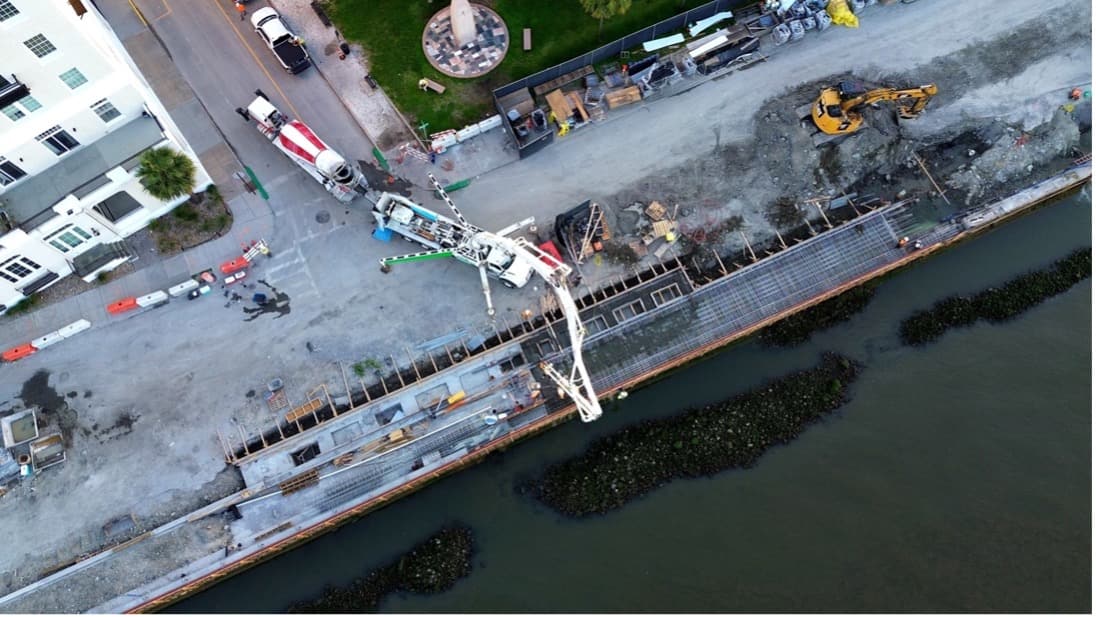

To maximize the lifespan and durability of the canal’s quay walls, the engineering team selected Mateenbar60™ Glass Fiber-Reinforced Polymer (GFRP) rebar.

Project Results

The key benefits Mateenbar60™ offered in the Marina Project included:

- Corrosion-Free Performance – Unlike steel rebar, Mateenbar60™ does not rust, making it ideal for long-term use in harsh marine environments.

- Enhanced Aesthetics – The quay walls remain free from rust stains and concrete spalling, maintaining the premium appearance of the waterfront development.

- Extended Service Life – With a design life exceeding 100 years, Mateenbar60™ fiberglass rebar surpasses the project’s 75-year requirement, reducing future maintenance and repair costs.

- Structural Efficiency – The use of Mateenbar60™ reduced the required concrete cover, allowing for thinner and more efficient pre-cast decorative quay wall panels.

- Optimized Strength and Flexibility – Mateenbar60™ bends and fiberglass rebar were strategically incorporated into areas of the main tunnel subjected to heavy loads, ensuring superior tensile strength and structural resilience.

By incorporating Mateenbar60™ into the quay wall construction, the project achieved a durable and cost-effective solution designed to withstand the harsh conditions of a coastal environment. The material’s lightweight nature also simplified handling and installation, contributing to overall project efficiency.

Why is GFRP Rebar Ideal for Marine Applications?

GFRP rebar, such as Mateenbar60™, offers a game-changing alternative to traditional steel reinforcement in marine and waterfront infrastructure projects.

It is lightweight, easy to cut, and corrosion-resistant, making it an ideal choice for applications where long-term performance and durability are essential.

With a service life exceeding 100 years, Mateenbar60™ provides a sustainable and maintenance-free reinforcement solution, ensuring the integrity of coastal developments for generations to come.

For more proof of the effectiveness of using fiberglass rebar in marine environments, check out how Mateenbar60™ was used on the Low Battery Seawall Repair Project in South Carolina.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.