Deep Stormwater Tunnel Project, Dubai

Project Overview

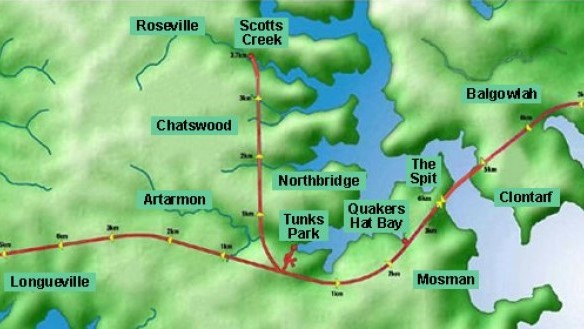

Dubai’s rapid urbanization and extreme weather conditions have made flood management a pressing priority. Even short rainfall events can lead to significant flooding, disrupting transportation, business operations, and critical infrastructure, including Al Maktoum International Airport and Expolink 2020 areas.

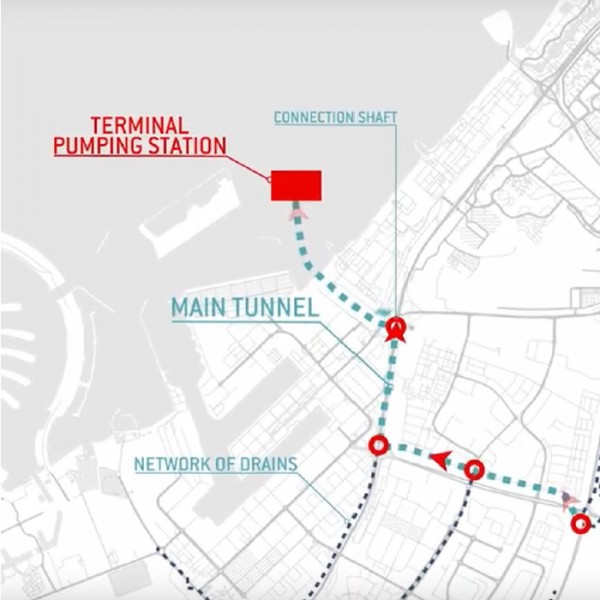

To address this, the Dubai Municipality commissioned a large-scale stormwater management project to collect and transfer groundwater and stormwater runoff from the wider Dubai World Central area.

At the heart of this ambitious initiative is a 6-mile-long stormwater tunnel, designed to drain nearly 40% of Dubai’s urban area.

With depths ranging from 98 to 148 feet and four deep shafts measuring 46 to 66 feet in diameter, this infrastructure is engineered to handle 6.5 million cubic meters of water—the equivalent of 2,600 Olympic-sized swimming pools.

The deep tunnel system allows gravity to manage most of the water flow, requiring only a single pumping station, making the system both energy-efficient and easy to operate.

A critical requirement for this project was to construct a maintenance-free tunnel with a 100-year design life, capable of withstanding Dubai’s harsh environmental conditions.

The inside of the tunnel will be subjected to stormwater carrying abrasive sand, while the exterior will be exposed to chlorides and sulfates that accelerate concrete deterioration.

To ensure long-term durability and efficiency, Mateenbar60™ fiberglass rebar was selected as the reinforcement solution.

Project Results

The integration of Mateenbar60™ delivered several key benefits across both phases of the project:

- Corrosion-Free Performance: Unlike traditional steel reinforcement, Mateenbar60™ does not corrode when exposed to chlorides, sulfates, or constant moisture, ensuring the tunnel structure remains intact over its 100-year design life.

- Seamless Tunnel Boring: The use of Mateenbar60™ allowed for fast, uninterrupted tunnel boring machine (TBM) operations, eliminating the risk of reinforcement breakage and avoiding costly project delays.

- Increased Structural Longevity: By mitigating the risk of concrete degradation caused by environmental factors, Mateenbar60™ fiberglass rebar helps ensure the tunnel remains maintenance-free, reducing long-term repair and operational costs.

- Lightweight and Easy to Handle: Mateenbar60™ is significantly lighter than steel rebar, making it easier to transport, handle, and install, which improves overall construction efficiency.

- Energy-Efficient Infrastructure: The deep tunnel design, reinforced with Mateenbar60™, allows gravity to perform most of the drainage work, minimizing the energy demand of the system’s single pumping station.

Implementation Across Project Phases

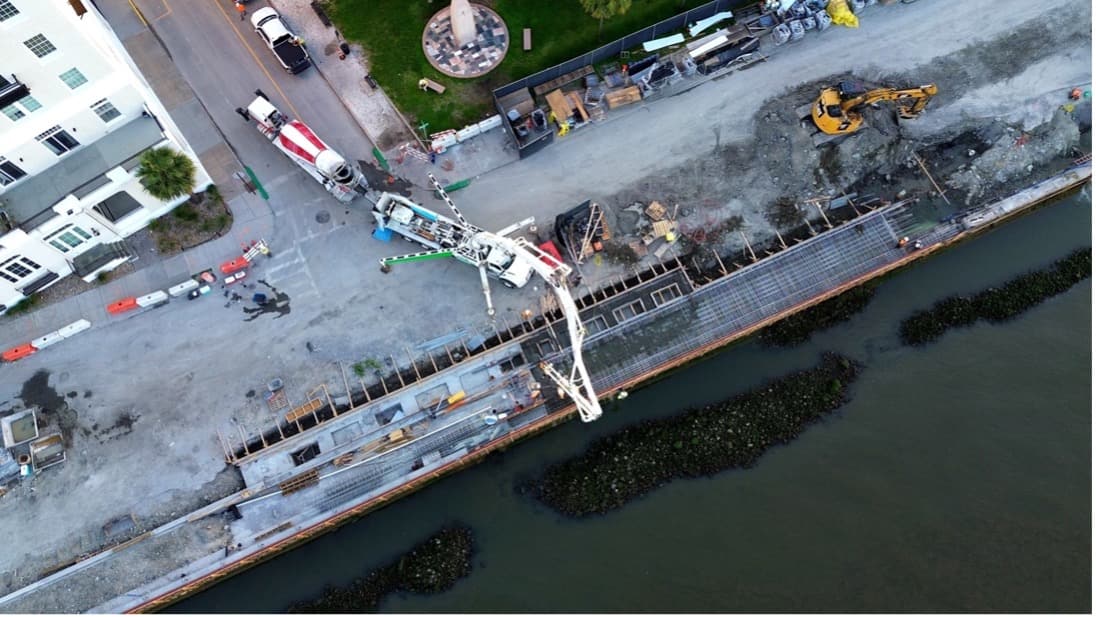

- Phase 1 – Tunnel Preparation

Mateenbar60™ was used to maintain overcuts, allowing TBMs to operate smoothly without reinforcement breakage. Mateenbar60™ bends were also used as GFRP concrete spacers on the sides of the primary panels. - Phase 2 – Main Tunnel Construction

Mateenbar60™ was used to reinforce the diaphragm walls (D-walls), ensuring safe, efficient, and fast tunnel boring across the 6-mile system. The combination of Mateenbar60™ and Mateenbar60™ bends significantly improved construction speed while enhancing the tunnel’s structural resilience.

- Phase 1 – Tunnel Preparation

By leveraging Mateenbar60™, Dubai’s stormwater tunnel is set to become a benchmark for flood mitigation infrastructure, providing a long-term, sustainable solution to the city’s drainage challenges.

This project demonstrates how advanced composite reinforcement materials can play a crucial role in building resilient, future-proof urban infrastructure.

Find out where you can buy Mateenbar® for your next project today.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.