Construction of 10 Schools, Marshall Islands

Project Overview

The Marshall Islands, located between Australia and Hawaii, consist of 34 low-lying islands built on volcanic rock and coral atolls.

With an average elevation of just 6.9 feet above sea level, the country faces significant challenges, including high population density, scarce freshwater resources, and limited funding for infrastructure.

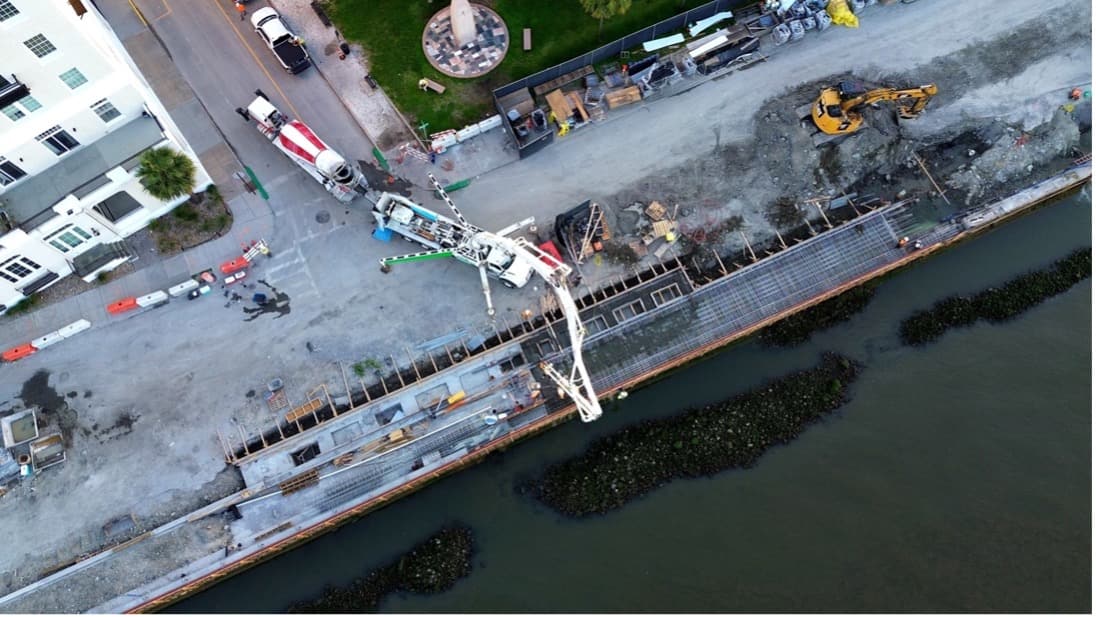

A key concern in the construction of 10 new schools was ensuring durability in an environment where exposure to salt, sand, and unwashed aggregates is unavoidable.

Traditional steel rebar, which corrodes rapidly in such conditions, typically has a life cycle of only 10 years before structural integrity is compromised.

Given the need for long-lasting, safe educational facilities, the project consultants, Beca, who have over 25 years of experience working in the Marshall Islands, sought a solution that could withstand these extreme conditions while providing lasting value.

Project Results

To address the unique environmental and material challenges, the project incorporated Mateenbar60™ glass fiber-reinforced polymer (GFRP) rebar as the reinforcement material of choice.

This innovative solution allowed for the use of locally available unwashed sand and concrete mixed with seawater without the risk of corrosion, significantly extending the lifespan of the school buildings.

Key benefits of using Mateenbar60™ in this project:

- Corrosion resistance –Mateenbar60™ fiberglass rebar does not corrode when exposed to chlorides and salt, preventing structural degradation over time.

- Extended design life – The schools will remain structurally sound for generations, ensuring long-term value from the U.S. aid agency funding.

- Lower maintenance costs – By eliminating corrosion-related deterioration, future repair and reinforcement expenses are significantly reduced.

- Adaptability to local resources – Mateenbar60™ allows for the use of naturally available sand and seawater in concrete mixes, reducing reliance on expensive imported materials.

- Sustainable infrastructure – The long-lasting durability of the schools helps create a stable and safe learning environment for Marshallese students well into the future.

By choosing Mateenbar60™, engineers and project stakeholders have ensured that the new schools will serve the community for decades, educating the next generation of students and providing a sustainable solution to the challenges of building in the Marshall Islands.

For other community-based, impactful projects Mateenbar60™ was used in, see our Structural Projects page.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.