Sea Water Plant Refinement, Saudi Arabia

Project Overview

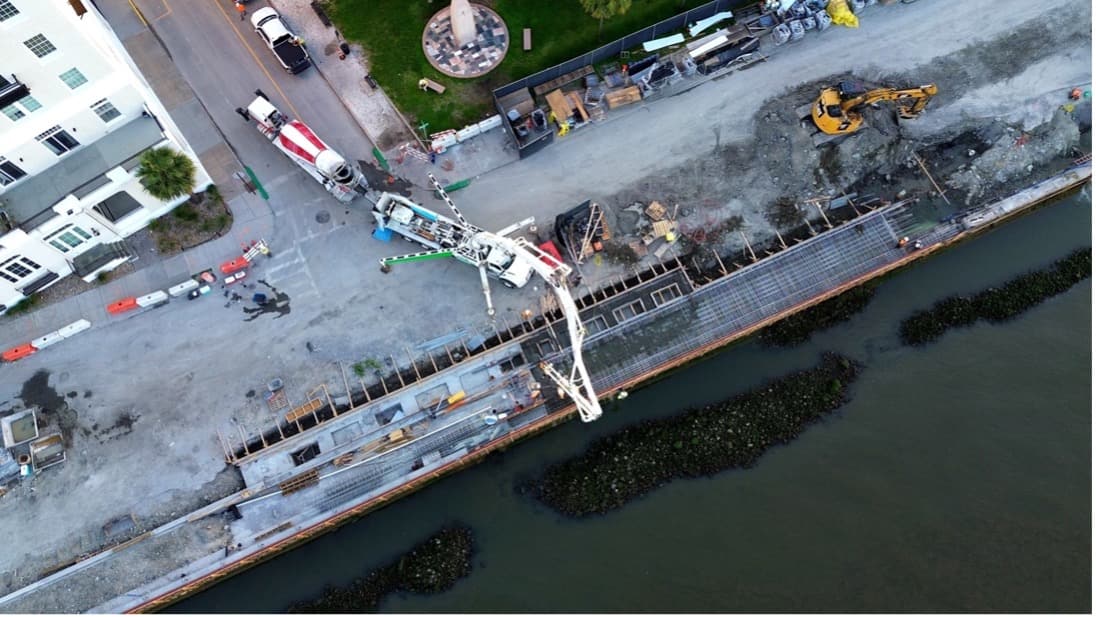

As part of Saudi Aramco’s commitment to integrating non-metallic materials into its projects, the Qurayyah Seawater Injection Department (QSWP) has undertaken a groundbreaking initiative—incorporating fiberglass reinforcement bars (GFRP) for the first time within the plant. This marks a significant step in Aramco’s ongoing efforts to enhance infrastructure longevity while reducing maintenance costs and environmental impact.

Seawater injection plays a crucial role in oilfield management, ensuring optimal reservoir pressure and improving oil recovery. Instead of depleting natural freshwater resources, the QSWP extracts seawater from the Arabian Gulf for injection into reservoirs.

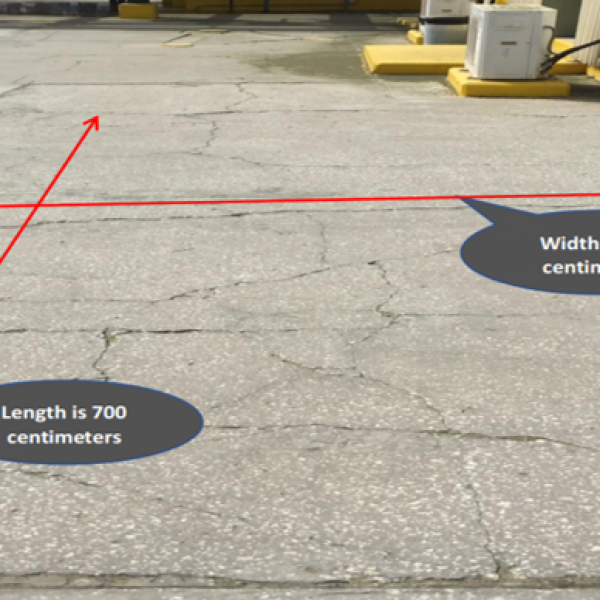

However, the facility’s constant exposure to high salinity, humidity, and extreme temperatures accelerates the deterioration of traditional concrete structures reinforced with steel. This has led to persistent maintenance challenges and costly repairs.

To address these issues, Mateenbar60™, a high-performance glass fiber-reinforced polymer (GFRP) rebar, was selected as the preferred reinforcement solution.

The Qurayyah plant’s adoption of this advanced material represents a shift towards sustainable, non-metallic infrastructure, reinforcing Aramco’s leadership in innovation and environmental stewardship.

Project Results

The integration of Mateenbar60™ at QSWP has delivered significant advantages in this highly corrosive environment:

- Corrosion-Free Reinforcement: Unlike steel rebar, Mateenbar60™ fiberglass rebar does not rust or degrade when exposed to high salinity, chloride-laden soil, and extreme humidity, ensuring structural durability over time.

- Extended Asset Lifecycle: With superior resistance to environmental stressors, Mateenbar60™ reduces the frequency of maintenance and repairs, leading to substantial cost savings for the plant.

- Enhanced Sustainability: By eliminating the need for frequent replacements and reducing material wastage, the adoption of Mateenbar60™ aligns with Aramco’s broader sustainability goals.

- Improved Construction Efficiency: Fiberglass rebar is significantly lighter than steel, making it easier to transport, handle, and install, ultimately accelerating project timelines.

- Supports Aramco’s Non-Metallic Initiative: The success of this pilot project underscores the potential for widespread use of non-metallic solutions across Aramco’s operations, reducing carbon emissions and enhancing infrastructure resilience.

The Qurayyah Seawater Injection Plant is the world’s largest seawater injection facility, and its adoption of Mateenbar60™ reinforces the role of GFRP technology in future-proofing critical energy infrastructure.

By integrating corrosion-resistant materials, Aramco is setting a new standard for sustainable construction in oil and gas operations.

The implementation of Mateenbar60™ in this pilot project is just the beginning of a broader transformation. As Aramco continues to drive innovation through its non-metallic initiative, the use of fiberglass rebar will play a pivotal role in reducing maintenance costs, improving asset longevity, and contributing to the company’s ambitious carbon reduction targets.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.