Port of Rotterdam Upgrade, Netherlands

Project Overview

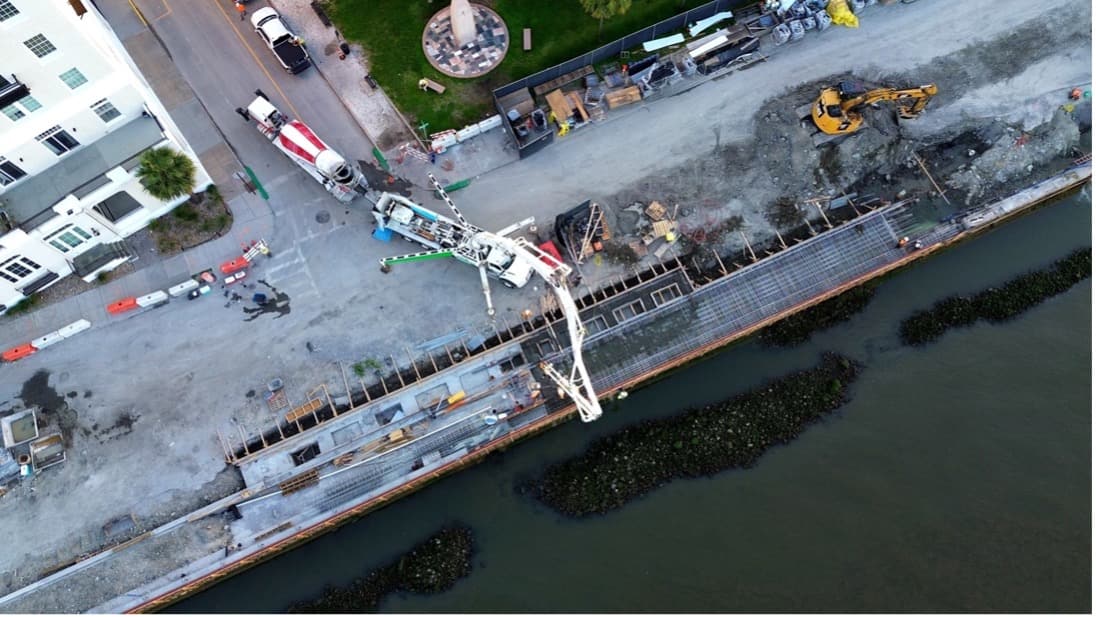

As Europe’s largest and busiest port, the Port of Rotterdam plays a vital role in global trade and logistics, handling millions of tons of cargo annually. Given its exposure to harsh maritime conditions, the port required an upgrade that would minimize maintenance disruptions and extend structural longevity.

To achieve this, engineers specified corrosion-resistant fiberglass rebar for key infrastructure improvements, particularly in areas subject to heavy loads and constant exposure to saltwater. Mateenbar60™ GFRP rebar was chosen as the preferred material due to its superior durability, lightweight properties, and corrosion resistance.

Rotterdam Port at a Glance

- Operates 24/7, 365 days a year.

- Covers a total area of 12,464 hectares.

- Manages approximately 30,000 ships and 105,000 inland water vessels annually.

- Features depths ranging from 24 to 26 meters in various areas.

- Accounts for 8.2% of the Netherlands’ gross domestic product (GDP).

Project Results

Enhanced Durability for AGV Pathways

One of the most critical aspects of the upgrade involved constructing reinforced concrete slabs to support the movement of Automatic Guided Vehicles (AGVs)—autonomous transport systems that handle cargo efficiently. Several key considerations influenced material selection:

- Corrosion Resistance – Traditional steel rebar is highly susceptible to chloride ingress from saltwater exposure, leading to deterioration over time. Mateenbar60™ GFRP fiberglass rebar and Mateendowel™ composite provide a corrosion-free solution, extending the lifespan of the concrete slabs.

- Vibration Management – AGVs create significant vibrations as they transport heavy loads. The reinforced slabs were designed and tested to withstand these forces, ensuring long-term performance.

- Load-Bearing Capacity – The concrete pathways were engineered to support the weight of AGVs and cargo while maintaining structural integrity under constant operational stress.

- Reduced Maintenance Costs – By using corrosion-resistant materials, the port significantly reduces the need for frequent repairs, minimizing disruptions to daily operations and achieving long-term cost savings.

Advantages of GFRP Rebar in Port Infrastructure

The integration of Mateenbar60™ rebar offered multiple advantages over traditional steel reinforcement:

- Rust-Resistant – Eliminates the risk of rust, ensuring long-term structural integrity in a high-salinity environment.

- Lightweight and Easy to Handle – Four times lighter than steel, reducing transportation costs and improving installation efficiency.

- Electromagnetic Transparency – Unlike steel rebar, fiberglass rebar reinforcement does not interfere with electronic systems, ensuring uninterrupted port communications.

- Fast and Efficient Installation – Mateenbar60™ features low bond strength, eliminating the need for greasing or special coatings, which streamlines the construction process.

Future-Proofing the Port of Rotterdam

The successful integration of corrosion-resistant Mateenbar60™ fiberglass rebar has reinforced critical port infrastructure while reducing maintenance costs and operational downtime. By adopting innovative, long-lasting materials, the Port of Rotterdam has strengthened its position as a global leader in maritime logistics—ensuring efficiency, durability, and sustainability for decades to come.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.