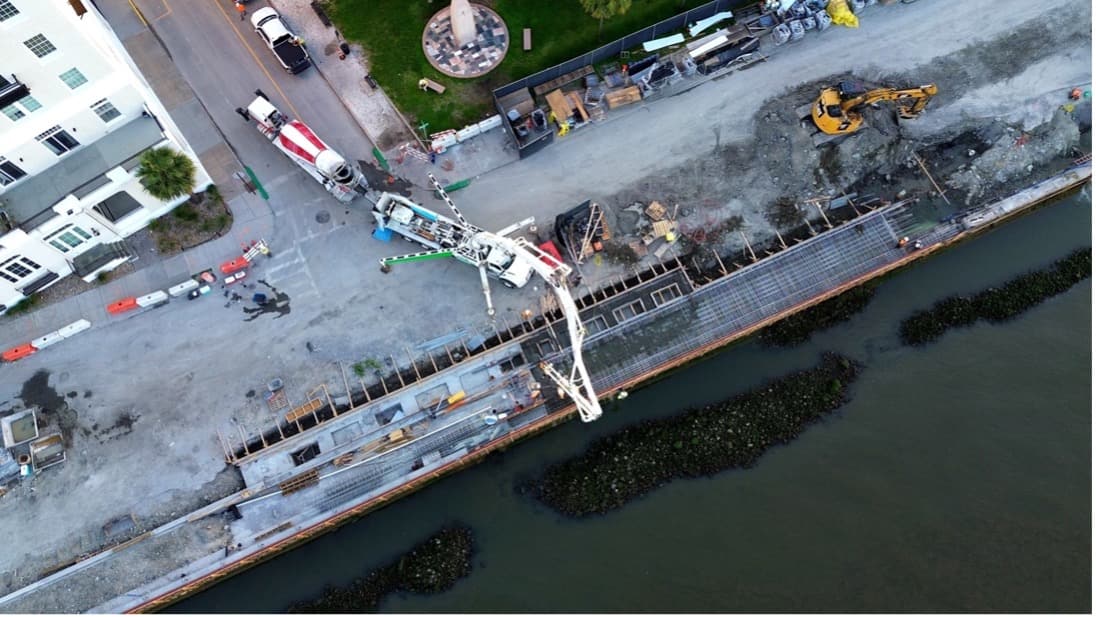

Desalination Plant Reinforcement, Australia

Project Overview

The Perth Seawater Desalination Plant in Western Australia is a critical infrastructure project that ensures a sustainable water supply for the region. As the largest desalination plant in the Southern Hemisphere, it has the capacity to produce 50 billion liters of fresh water annually, playing a vital role in addressing water scarcity.

Constructing such a large-scale facility required materials that could withstand the harsh marine environment and corrosive conditions associated with desalination processes. Mateenbar60™ fiberglass rebar was chosen as the primary reinforcement material due to its superior durability, corrosion resistance, and long-term performance benefits.

Project Results

- Corrosion Resistance for Long-Term Integrity Traditional steel reinforcement is highly susceptible to corrosion in desalination plants due to exposure to hypersaline water. Mateenbar60™, being a Glass Fiber-Reinforced Polymer (GFRP) rebar, is entirely corrosion-resistant. This ensures the long-term structural integrity of the plant, reducing the need for costly maintenance and extending the facility’s operational lifespan.

- Enhanced Durability & Reduced Maintenance Costs Mateenbar60™ offers exceptional resistance to chemicals and harsh environmental conditions, making it ideal for the extreme marine exposure at the Plant. By using GFRP fiberglass rebar, the desalination plant benefits from a 100-year design life with minimal maintenance, significantly lowering long-term costs for infrastructure upkeep.

- Improved Installation Efficiency One of the key advantages of Mateenbar60™ is its lightweight composition compared to traditional steel reinforcement. This makes transportation, handling, and installation much easier, reducing labor demands and expediting the construction process. The use of fiberglass rebar contributed to overall project efficiency, helping to meet deadlines and control construction costs.

- Pioneering Sustainable Infrastructure As the construction industry shifts toward sustainable solutions, the use of Mateenbar60™ at the Plant sets a new benchmark for infrastructure resilience. By eliminating corrosion-related failures and reducing lifecycle costs, this project highlights the advantages of GFRP reinforcement in mission-critical facilities.

The successful implementation of Mateenbar60™ at the Perth Seawater Desalination Plant underscores its effectiveness as a long-term, sustainable reinforcement solution. This project serves as a model for future infrastructure developments worldwide, demonstrating how innovative materials can enhance performance, durability, and sustainability.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.