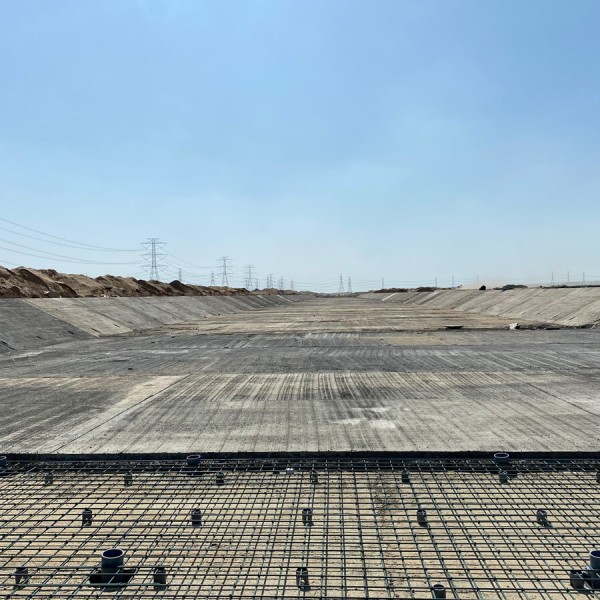

Jizan Flood Mitigation Channel, Saudi Arabia

Project Overview

The world’s largest Glass Fiber-Reinforced Polymer (GFRP) rebar project was successfully completed in 2022.

Corrosion-resistant GFRP fiberglass rebar was specified as the exclusive reinforcement material for the Jizan Flood Mitigation Channel in Saudi Arabia. Mateenbar60™ was selected as the primary supplier of GFRP reinforcement for the project, marking a significant step in sustainable infrastructure development and a very proud moment for Mateenbar® itself.

Jizan Economic City, a key industrial and commercial hub on the Red Sea, is home to Saudi Aramco’s Jizan oil refinery, which processes 400,000 barrels of crude per day. However, the region faced a serious flooding risk due to inadequate drainage systems and heavy seasonal rainfall. To address this challenge, Saudi Aramco initiated the construction of a 14-mile-long Flood Mitigation Channel to protect infrastructure and residents.

As part of its non-metallic initiative, Saudi Aramco mandated the use of GFRP rebar to reduce long-term corrosion costs and enhance sustainability.

Project Results

- Enhanced Durability & Corrosion Resistance: The use of Mateenbar60™ fiberglass rebar ensures the channel’s long-term durability by eliminating corrosion risks, contributing to a 100-year design life with minimal maintenance.

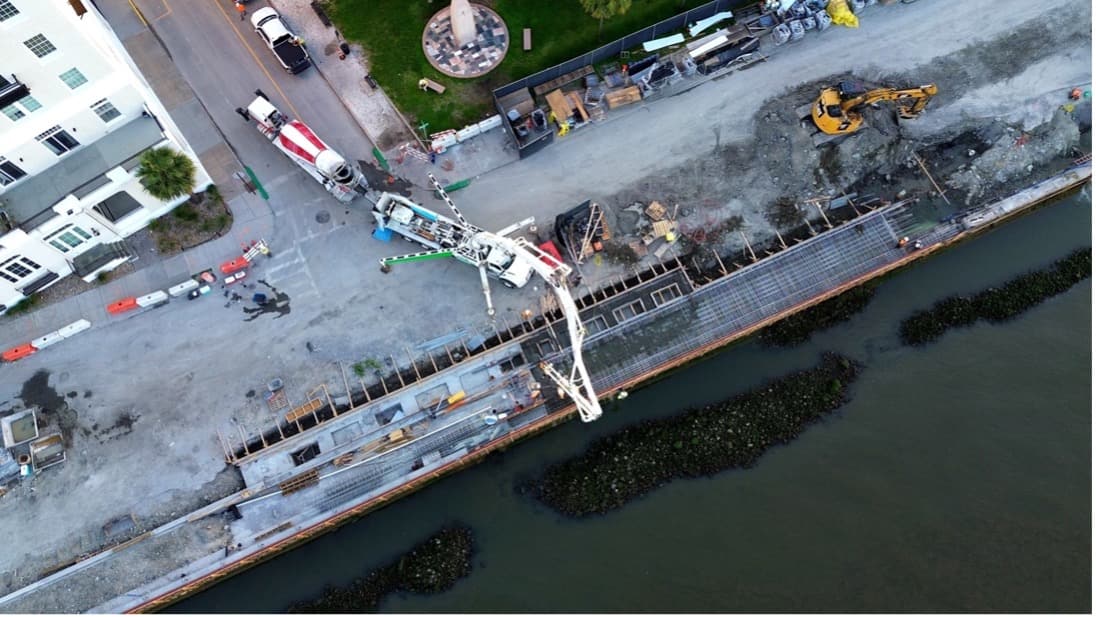

- Efficient & Rapid Construction: The construction team poured over 53,000 cubic feet of concrete daily, making it one of the fastest channel construction projects ever undertaken. Almost 3,000 miles of Mateenbar60™ were delivered, with nearly 25% consisting of preformed bends in various shapes.

- Scaling Production to Meet Demand: Adjustments in project scope required increased production capacity. Mateenbar® responded by installing additional automated grinder units and a new bends machine, ensuring timely delivery. Collaboration with Pultron Composites facilitated rapid production scaling and met construction deadlines.

- Innovative Structural Design: The flood channel’s design required expansion joints in each slab, necessitating complex preformed bends. Pultrusion experts successfully engineered these bends, overcoming design challenges and ensuring seamless installation.

- Sustainability & Long-Term Benefits: By replacing traditional steel rebar with corrosion-resistant fiberglass rebar, the Jizan Flood Mitigation Channel represents a major advancement in sustainable infrastructure. The channel will protect Jizan’s residents and assets from flood damage while significantly reducing long-term maintenance costs.

The Jizan project sets a global benchmark for large-scale GFRP rebar use, paving the way for future infrastructure developments that prioritize durability and sustainability.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.