Grand Paris Express Construction, France

Project Overview

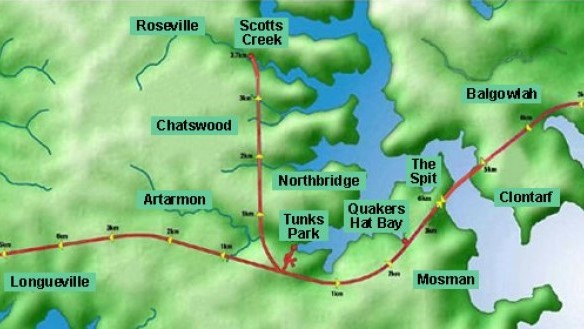

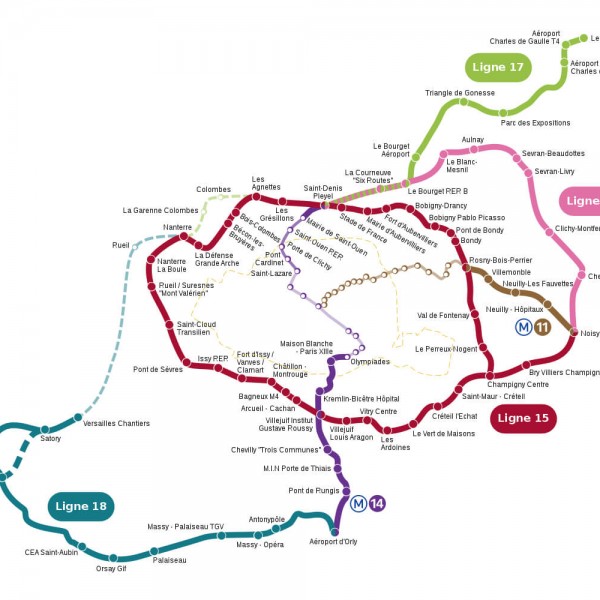

Paris is undergoing a significant transformation to accommodate its rapid growth and future urban mobility needs. The Grand Paris Express is one of the largest transportation projects in Europe, expanding the city’s metro network with 120 miles of new track and 68 new stations. Once completed, it will serve an estimated two million passengers daily, easing congestion and improving connectivity across the region.

As part of this ambitious project, Mateenbar60™ was supplied to two separate contractors working on the same metro line in different locations.

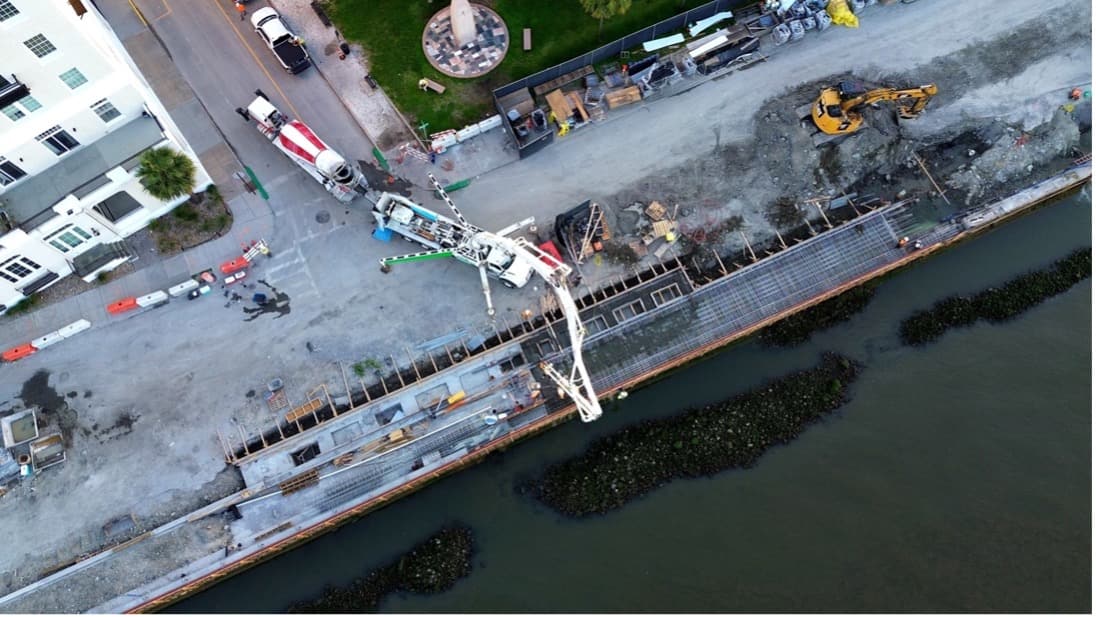

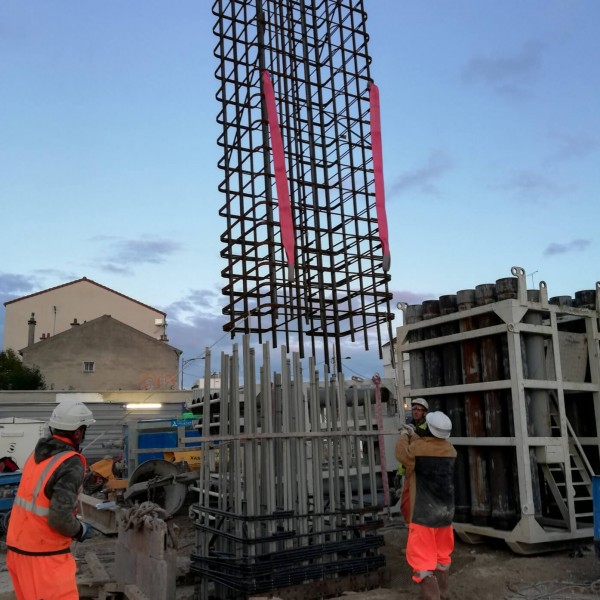

A major component of the project involved the construction of a four-mile tunnel with a 46-ft boring diameter at a depth of 230 feet. Additionally, a new metro station required diaphragm walls with a thickness of roughly 6 ft. Various diameters of Mateenbar60™ were used to meet the specific reinforcement needs of the project:

- Mateenbar60™ in varied diameters: 25/32/38 mm

- Mateenbar60™ bends in diameters: 14/20/25 mm

Engineers designed the structures using ACI 440 design standards to ensure structural integrity and optimal performance. Diaphragm walls were reinforced with Mateenbar60™ fiberglass rebar, allowing seamless excavation with tunnel boring machines (TBMs), improving productivity, and reducing costly delays.

Project Results

The use of Mateenbar60™ in the Grand Paris Express project provided multiple benefits, particularly in tunnel construction:

- Improved Efficiency in Tunnel Boring: Unlike traditional steel reinforcement, GFRP fiberglass rebar does not need to be removed before excavation, eliminating time-consuming and hazardous manual removal processes.

- No Risk of TBM Damage: Mateenbar60™ “softeyes” enable TBMs to cut through reinforced sections without damaging machinery, preventing costly repairs and downtime.

- Accelerated Construction Schedules: The ease of cutting through GFRP rebar speeds up the excavation process, keeping the project on track for timely completion.

- Enhanced Worker Safety: Removing steel reinforcement before boring is not only slow but also poses significant safety risks. Using fiberglass rebar eliminates these dangers, creating a safer work environment.

- Lightweight and Easy Handling: GFRP rebar is four times lighter than steel, making it easier to transport and install, especially in confined spaces where heavy machinery cannot be used.

By incorporating Mateenbar60™ in key structural elements, the Grand Paris Express project is setting a new standard for efficient, safe, and durable metro construction.

With enhanced productivity, cost savings, and long-term resilience, this infrastructure expansion will support Paris’s growth for generations to come while making the daily commute of residents much more efficient.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.