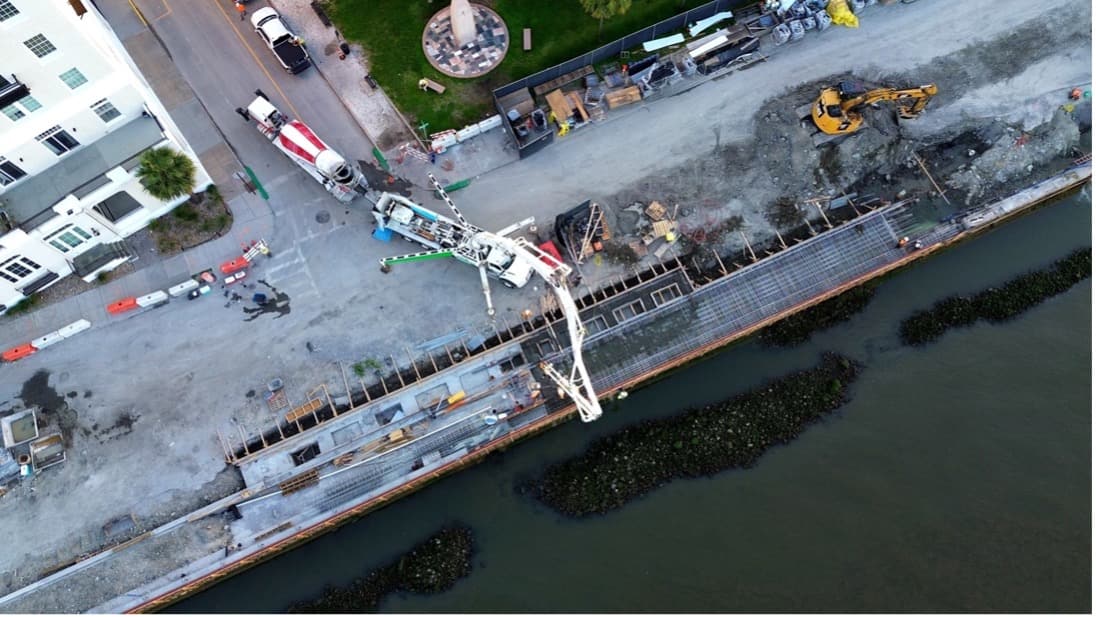

Harkers Island Bridge Replacement, USA

Project Overview

The Harkers Island Bridge project in North Carolina is a groundbreaking achievement in modern infrastructure, setting a new standard for sustainable bridge construction. Easy access to and from the island is not only important for daily commuters, but it’s especially imperative in emergencies and hurricane evacuations in the coastal region.

As the world’s largest bridge built entirely without steel reinforcement, this 3,200-ft-long, 28-span structure demonstrates the transformative potential of Glass Fiber Reinforced Polymer (GFRP), also called fiberglass rebar, in large-scale infrastructure projects.

The two bridges that preceded the new GFRP-reinforced bridge were deteriorating and due for replacements. Initially built in 1969, the Harker’s Island Bridges were more than 50 years old – which is when steel reinforcement can start to corrode, especially in marine environments. Since the bridge is the only way for people to get from the island to the mainland by vehicle, the importance of this project could not be overstated.

Read more about the purpose behind the Harker’s Island Bridge Replacement.

Given the harsh coastal conditions, engineers decided to go in a different direction with the new bridge’s reinforcement and select GFRP for structural integrity. They chose Mateenbar60™ fiberglass rebar in various sizes (#4, #5, #6, and #8) to provide exceptional structural integrity while eliminating the risks associated with steel corrosion in marine environments.

Project Results

By utilizing GFRP fiberglass rebar reinforcement, the project team ensured a solution that would provide:

- Corrosion resistance –GFRP does not rust or degrade when exposed to marine environments or harsh coastal conditions, reducing the need for costly maintenance. Corrosion is one of the main reasons why America’s bridges are aging.

- Extended service life – Mateenbar60™ is designed for a 100-year design life, significantly enhancing the longevity of the bridge while reducing long-term repair costs.

- Lightweight properties – Easier handling and installation compared to traditional steel reinforcement, increasing efficiency on-site.

- Sustainability benefits – A durable and sustainable structure reduces the environmental impact over its lifecycle.

- BABA-Compliant & American-Made – Proven reliability for federally funded infrastructure projects.

The project successfully integrated 1,574,618 linear feet of Mateenbar60™ GFRP reinforcement, marking a historic shift away from steel-reinforced bridges.

The new bridge features 125 ft of horizontal clearance and 45 ft of vertical clearance, allowing boats and ships to move through the area smoothly while letting drivers cross without delays from a drawbridge opening.

The Future of Bridge Reinforcement

The Harker’s Island Bridge is more than a vital transportation link—it is a pioneering project that showcases the effectiveness of using GFRP fiberglass rebar as the future reinforcement of bridges worldwide.

In an article posted by PCI on the Project, Trey Carroll, PE, assistant state structures engineer with NCDOT, had this to say about using GFRP technology instead of traditional steel:

“The use of noncorroding fiber-reinforced polymer is a demonstrated, viable alternative to steel. Typical maintenance and repair associated with steel-reinforced concrete is eliminated, increasing the useful service life and resilience of the structure.”

By eliminating the risk of corrosion and significantly extending the bridge’s lifespan, this structure stands as a model for resilient and sustainable infrastructure worldwide.

Harker’s Island Bridge – An Award-Winning Project

The project won two 2025 PCI Design Awards – the Harry H. Edwards Industry Advancement Award and Best Bridge with a Main Span from 76-200 Feet – for its successful implementation.

We are honored that Mateenbar60™ contributed to this award-winning project, reinforcing not just the bridge, but the vital role it plays in linking communities, enhancing accessibility, and supporting the infrastructure that unites people.

This achievement reflects our fundamental belief that infrastructure goes beyond materials—it’s about strengthening the connections that matter most.

Want to see an additional case study of how Mateenbar60™ is transforming bridge construction? Check out the Liberty Bridge Project—another award-winning example of innovation and durability in action.

Building the Future with Mateenbar®

For over 30 years globally, Mateenbar® has been a leader in strength, purpose, and sustainable innovation—proudly made in the USA and fully BABA-compliant. When infrastructure projects demand proven durability, superior performance, and long-term resilience, Mateenbar60™ is the smart choice. Contact our team today to learn how GFRP rebar can optimize your next project, reduce lifecycle costs, and deliver lasting results. Discover why Mateenbar® reinforces what matters most—building the future of infrastructure, one project at a time.